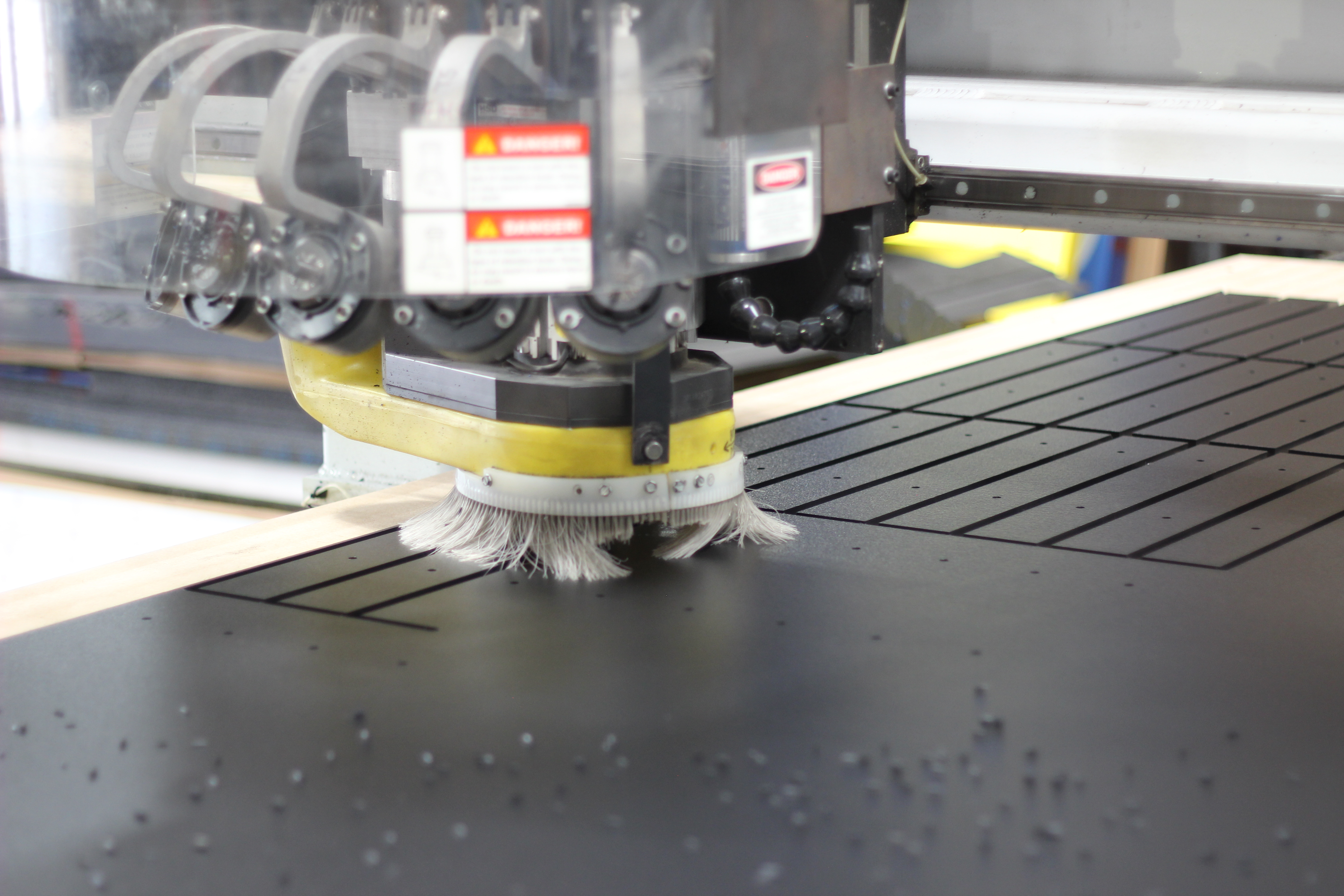

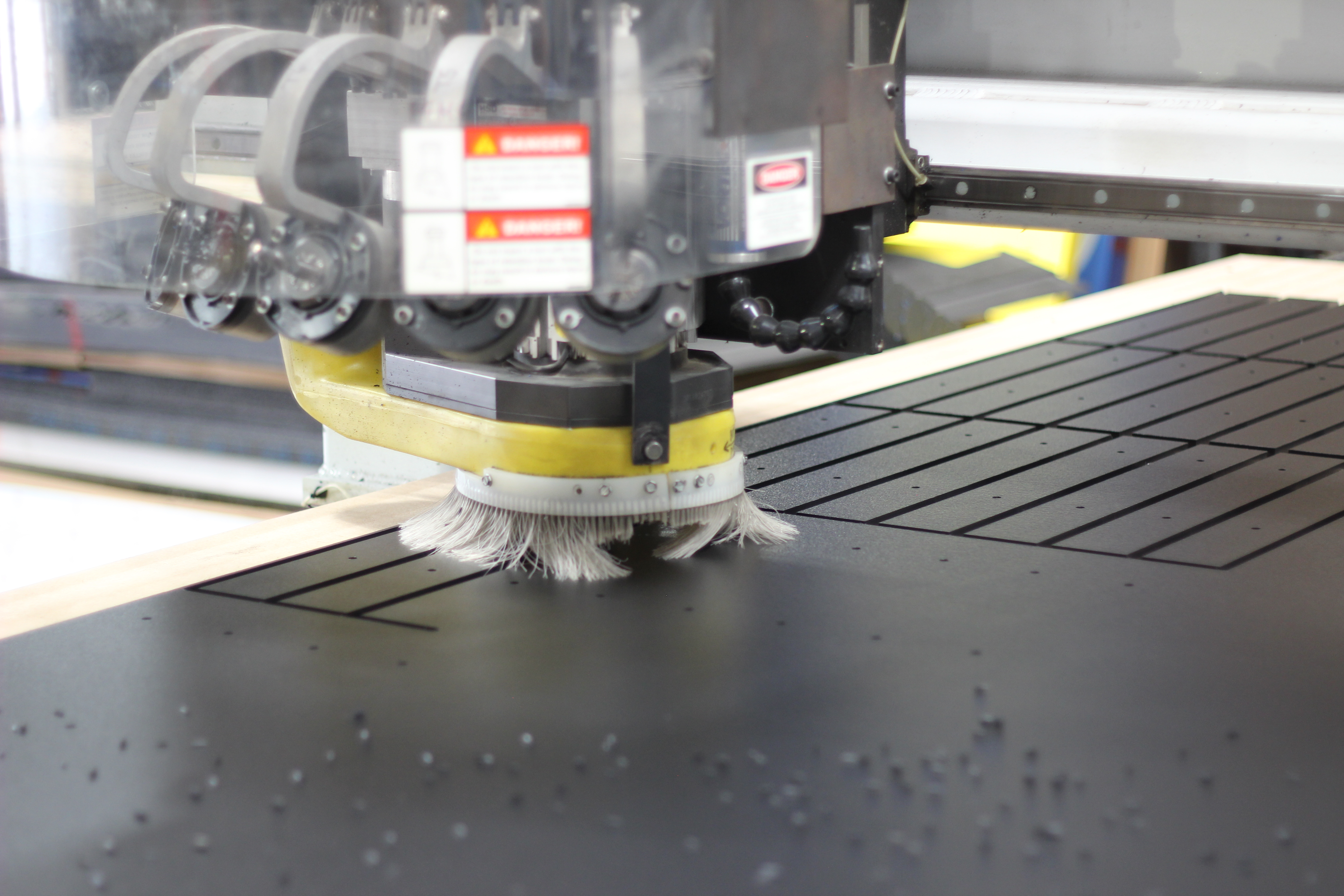

From picking up raw materials to delivering finished parts, Cutting Experts provides full service precision CNC routing of close tolerance flat or 3D shaped parts. We use high speed, state-of-the-art Thermwood equipment to cut, trim, and shape a wide variety of materials including aluminum, wood, foam, composite, and plastic.

We have created prototypes and precision orders for a wide range of industries such as food processing, poultry, lumber, aerospace and many more that rely on precisely cut abrasion resistant plastic parts.

Our 3-axis capabilities offer a build envelope of 120″ x 60″, and a 7-position tool changer provides the ability to fabricate richly detailed parts quickly and with tolerances to ± .003″. We use only NIST certified measuring equipment to verify dimensional specifications.

Our professional team works with you each step of the way to ensure specifications, quality standards, and delivery schedules are met. We welcome you to supply your own materials, or we can source it for you at a reasonable cost, a service our competitors do not offer. Examples of parts we produce include foam packaging inserts, architectural metal fabrications, signs, and industrial component parts.

Cutting Experts uses advanced production planning and CNC organizational software that allows large jobs to stay on track and organized and small jobs to flow quickly through the schedule. Over the years we have processed tens of thousands of CNC jobs ranging from prototypes to very small orders, to large production orders. Our organized workflow is the key to successfully delivering your parts to you in an efficient manner.

For more information on how our precision CNC routing services can benefit your next application, contact us today.

Precision CNC Routing Specifications

| Production Grade Equipment | CNC Controlled Vacuum Table 7 Position Tool Changer |

| Cutting Axis | 2-Axis |

| Intended Cutting Material (Metal) | Aluminum |

| Intended Cutting Material (Non-Metal) | Foam Packaging XLPE Tool Inserts Wood |

| Intended Cutting Material (Industrial Plastics) | Nylon UHMW HDPE Polycarbonate Acrylic |

| Cutting Length | Up to 120 in |

| Cutting Width | Up to 60 in |

| Tolerance (+/-) | Up to .003 in |

| Production Volume | Prototype to Production Runs |

Additional Information

| Industry Focus | Architectural Metal Fabrication |

| Intended Application | Signs Industrial Parts from Plate |

| Industry Standards | NIST Certified Measuring Equipment |

| File Formats | AutoCAD MasterCAM Others |

CNC Router Basics

Computer Numeric Control (CNC) machines are perhaps one of the most revolutionary forms of technology used to ensure precision and increase efficiency when it comes to cutting, trimming, and shaping materials. From steel and wood to composites and foam, CNC routers are helping to maximize productivity in shops nationwide. Understanding it’s basic function helps one to appreciate just how valuable and resourceful such a piece of machinery is.

Since the first handheld router was created in 1915, the technological advances in the world of precision cutting seem unparalleled to some.

Essentially, the CNC router is able to take a piece of material, which could range from plywood to aluminum- and is able to trim the material to a precise measurement based upon what the client wants and needs. This is achieved by a multi-step process. Once a design is entered into a software program, the cutter is selected, the material is secured, and the routing process begins. The actual cutting process happens automatically. The router operates and cuts on three different axes, meaning there can be little-to-no limit on what shape and cut can be ultimately achieved.

What once was a lengthy process of repeated sawing and sanding has now been replaced by a practical, time-saving piece of machinery that will continue to provide precision cut products.