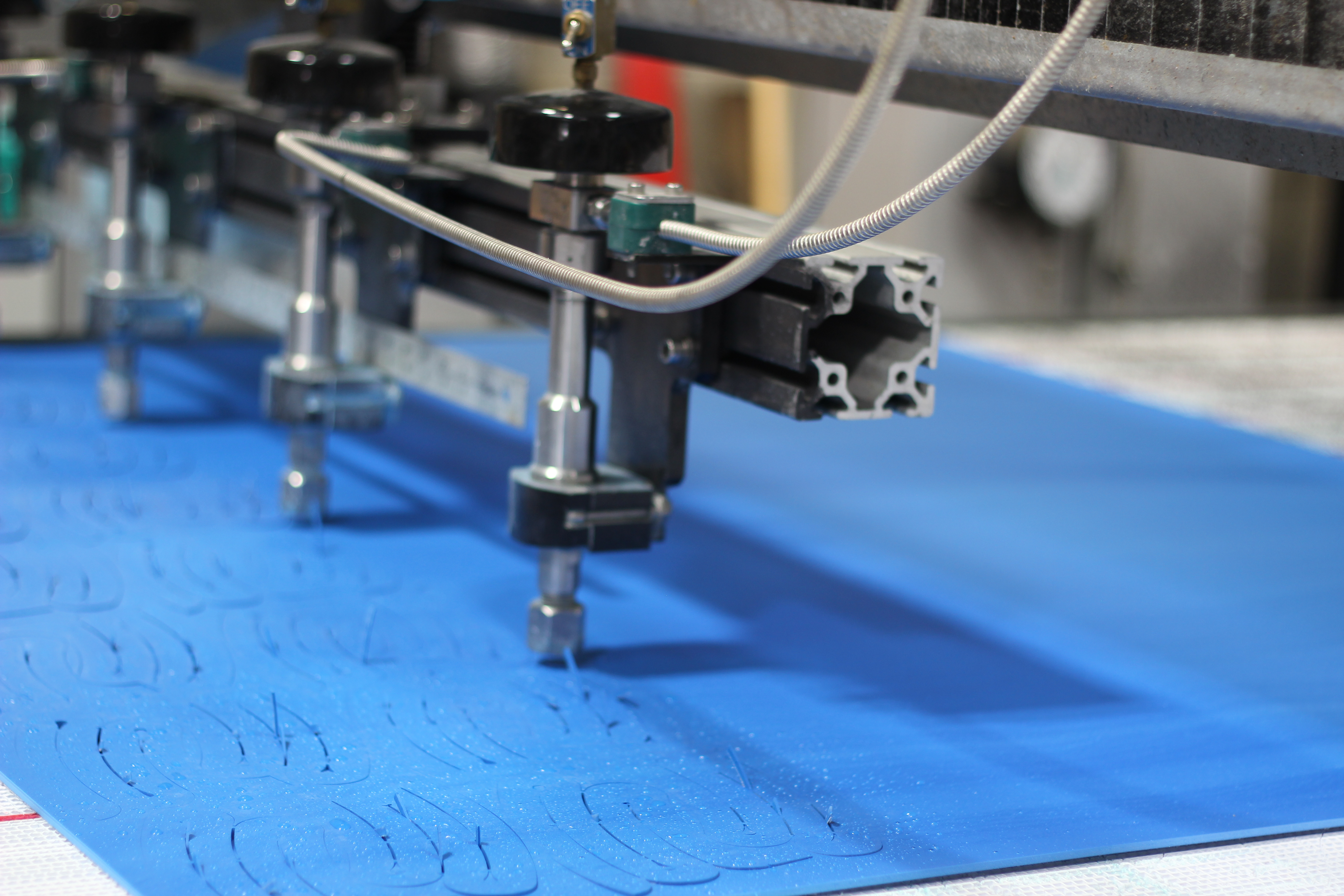

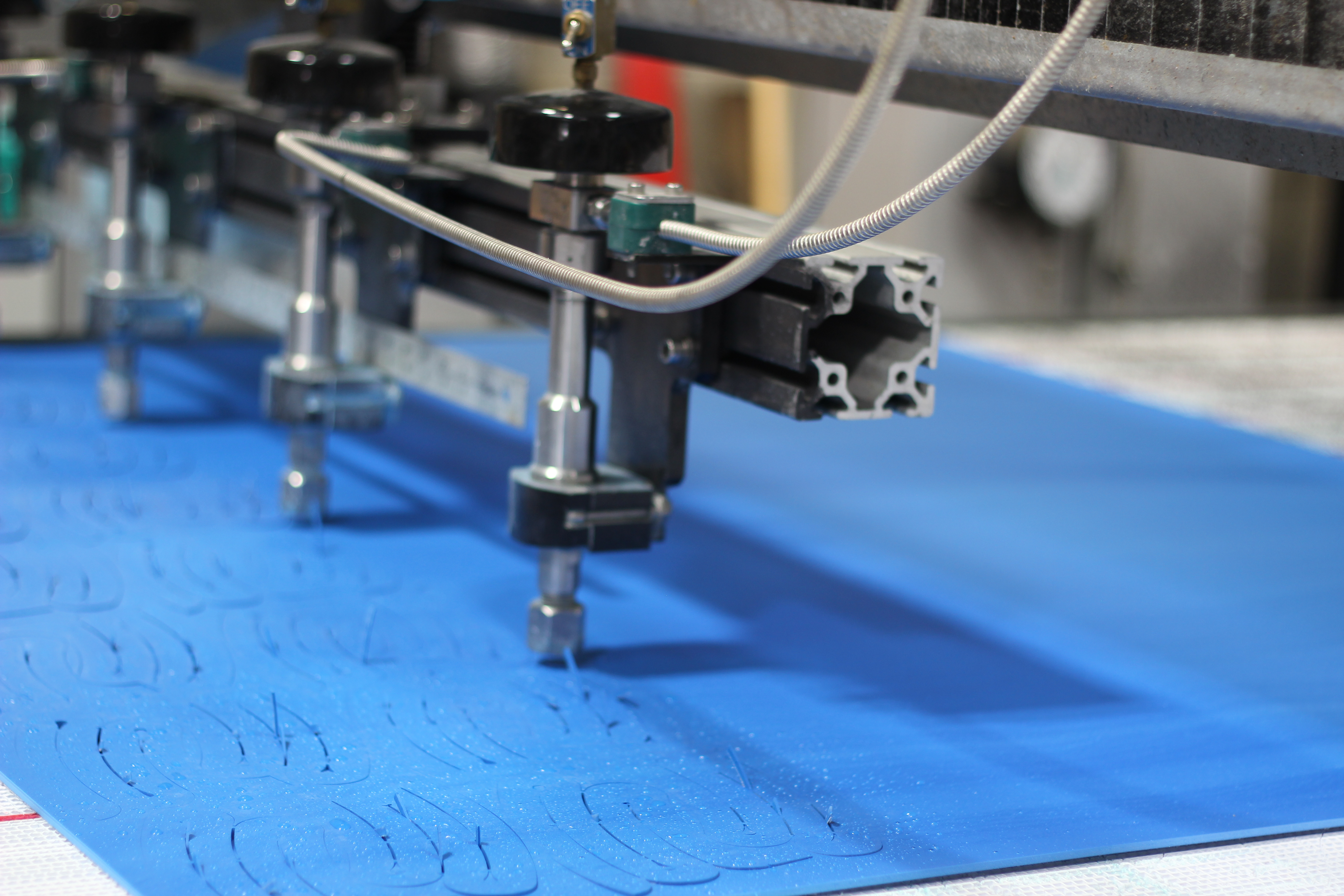

Cutting Experts precision waterjet cutting services provide close tolerance, distortion-free parts with superior edge quality, no burrs, and little need for secondary finishing. We specialize in both architectural and industrial cutting of high quality parts from any type of industrial plastics such as UHMW, HDPE, Starboard, Delrin, polypropylene, ABS, Teflon, Polycarbonate, acrylic, PVC and other abrasive resistant plastics.

Additionally, Cutting Experts and can handle other industrial materials, such as a wide variety of metals, foam, glass, tile, and stone.

Cutting Experts uses advanced production planning and CNC organizational software that allows large jobs to stay on track and organized and small jobs to flow quickly through the schedule. Over the years we have processed tens of thousands of CNC jobs ranging from prototypes to very small orders, to large production orders. Our organized workflow is the key.

Utilizing advanced part nesting techniques enables us to minimize material waste, and we pass that saving on to you. Our high speed 2-axis equipment is able to generate up to 60,000 psi to cut through material up to 5″ thick at speeds up to 600″/minute. Able to create complex shapes and intricate patterns, we fabricate parts measuring up to 144″ x 77″ at tolerances to ± 003″, which is verified by NIST certified measuring equipment.

Ensuring customer satisfaction is a critical part of our operation. When you call Cutting Experts, you will be greeted by a member of our professional staff, not an automated answering system. Our service staff will pick up raw material from your location in the metro Atlanta area and deliver the finished parts, at no additional charge to you. We will work with your CAD files, or digitally duplicate the part if a drawing is not available. In quantities from prototype to full production runs, we offer fast turnaround and very reasonable prices.

Precision CNC Waterjet Cutting Specifications

| Characteristics | Removes Taper Minimum Part Stress No Thermal Distortion or Hardening Reduced Material Cost Through Nesting Reduction or Elimination of Secondary Operations Smooth Finished Edges |

| Process | Water Abrasive |

| Cutting Axis | 2-Axis |

| Intended Cutting Material (Metal) | Stainless Steel Carbon Steel Aluminum Copper Bronze Brass Monel Inconel Hastelloy Titanium Nickel Alloys Others |

| Intended Cutting Material (Non-Metal) | Plastics Rubber Foam Phenolic Glass Tile Ceramic Stone |

| Intended Cutting Material (Industrial Plastics) | Mylon UHMW HDPE Polycarbonate Acrylic |

| Cutting Thickness | Up to 5 in |

| Cutting Length | Up to 144 in |

| Cutting Width | Up to 77 in |

| Waterjet Pressure | 60,000 psi |

| Cutting Speed | Up to 600 in/min |

| Kerf | .005 to .040 in |

| Tolerance (+/-) | Up to .003 in Depending on material and design |

| Production Volume | Prototype to Production Runs |

Additional Information

| Industry Focus | Architectural Metal Fabrication |

| Intended Application | Signs Industrial Parts from Plate |

| Industry Standards | NIST Certified Measuring Equipment |

| File Formats | AutoCAD MasterCAM Others |

Advantages

Our sophisticated waterjet cutting technology has significant competitive advantages over traditional cutting methods. A combination of speed and cost makes waterjet cutting the solution to your next cutting job.

| Requirements | Waterjet | EDM | Laser | Plasma | Machine Tools |

|---|---|---|---|---|---|

| Cost and time efficient | Yes | No | Yes | Yes | No |

| High tolerance, precise cutting | Yes | Yes | Yes | No | No |

| No burned edges, no HAZ | Yes | No | No | No | Yes |

| Multi-head cutting | Yes | No | Yes | No | Yes |

| Material is over .250 inch thick | Yes | Yes | No | Yes | Yes |

| No distortion or discoloration | Yes | Yes | No | No | No |

| Not conductive parts | Yes | No | Yes | Yes | Yes |

| Nesting yield | Yes | Yes | Yes | No | No |

| Shiny, mirror finish | Yes | Yes | No | No | Yes |

| Brittle, soft or hard material | Yes | Yes | Yes | Yes | No |

| Stainless steel, copper, brass or exotic material | Yes | Yes | No | Yes | No |

| Suitable for additional machining | Yes | No | No | No | Yes |

| No toxic fumes, deposits or carbon buildup | Yes | No | No | No | No |

| Environmentally friendly | Yes | No | Yes | Yes | No |

Waterjet Basics

The waterjet process provides many unique capabilities and advantages that can prove effective in your ongoing battle to reduce costs, increase efficiencies, and maintain quality in your shop. The more you know about waterjet technology, the better you’ll be able to understand the benefits it can bring to your operation.

Waterjets entered the manufacturing scene in the early 1970’s cutting soft materials like cardboard. In the mid 1980’s, the abrasive waterjet was invented by a team led by Dr. Mohamed Hashish at Flow, expanding the capabilities of the tool to cut hard materials. The basic technology is simple, yet complicated at the same time.

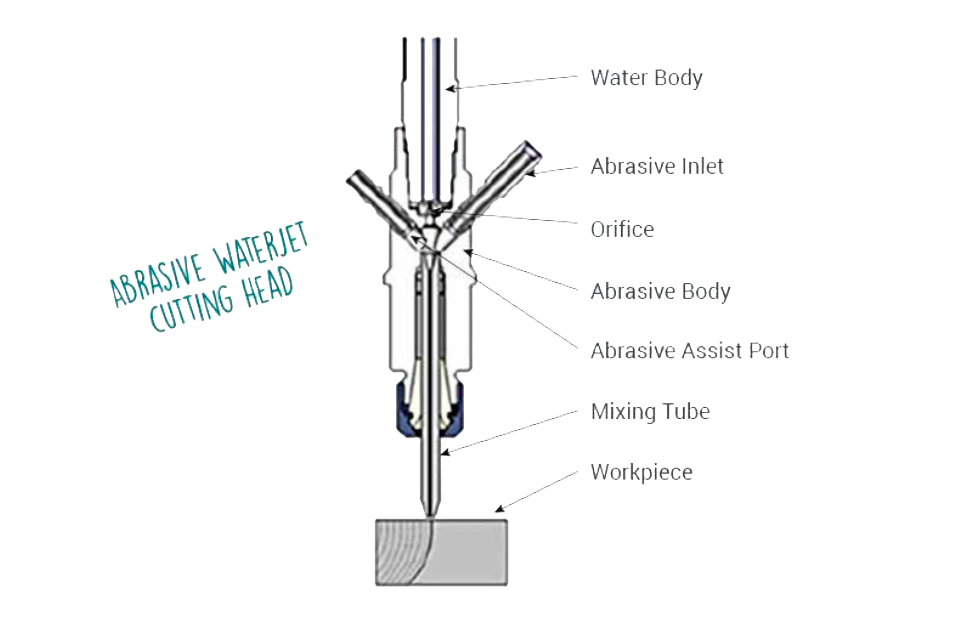

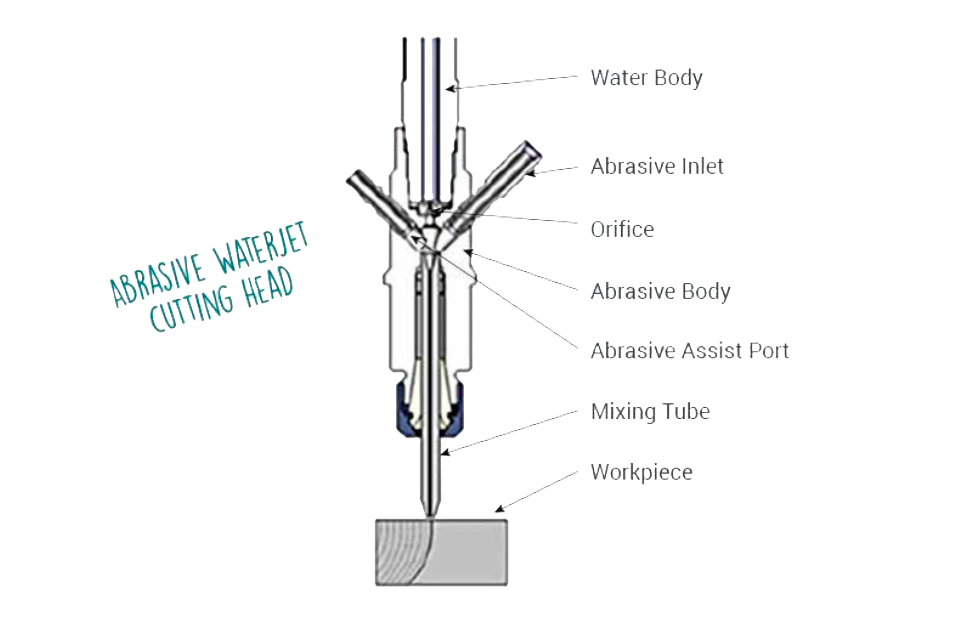

At its most basic, water flows from a pump, through plumbing and out a cutting head. It’s simple to explain, operate, and maintain. The process, however, incorporates extremely complex materials, technology, and design. Waterjet pumps today are usually rated to pressures between 60,000 and 94,000 psi (~4100 to 6400 bar). To put it in perspective, your home water pressure is about 60 pounds per square inch (~4 bar) and a fire hose delivers about 200 psi (~14 bar). In the waterjet machine tool, the pressurized water safely runs to the cutting head through ultrahigh-pressure plumbing comprised of T’s, elbows, swivels, and flexible stainless steel lines with diameters from ¼” OD to 9/16” OD (6.35 to 14.3 mm outside diameter). At the cutting head, a high speed air actuated On/Off Valve allows the water to pass through the jewel orifice creating a supersonic waterjet stream.

Despite the high psi, waterjets don’t actually cut with pressure but instead rely on velocity. The water pressure is exchanged for velocity when the water passes out of the cutting head’s orifice. The higher the pressure, the higher the stream velocity. At 60 psi, tap water out of a faucet is traveling 64 miles per hour (103 km/hr). At 94,000 psi, the waterjet is traveling nearly 2,500 miles per hour (4,000 km/hr) — more than three times the speed of sound.