How Much Does Waterjet Cutting Cost?

Cutting large or bulk materials seems like an extremely daunting and expensive task.

It’s actually much simpler and could be cheaper than you think!

If you’re looking for an exceptionally precise cut with virtually no secondary finishing required, and many other unique benefits, then waterjet cutting might be the right choice for you.

On top of the many benefits of waterjet cutting, it is also a very reasonably priced service based on your needs.

Let’s check out the process that determines how much you are going to spend on your waterjet cutting needs:

The Process

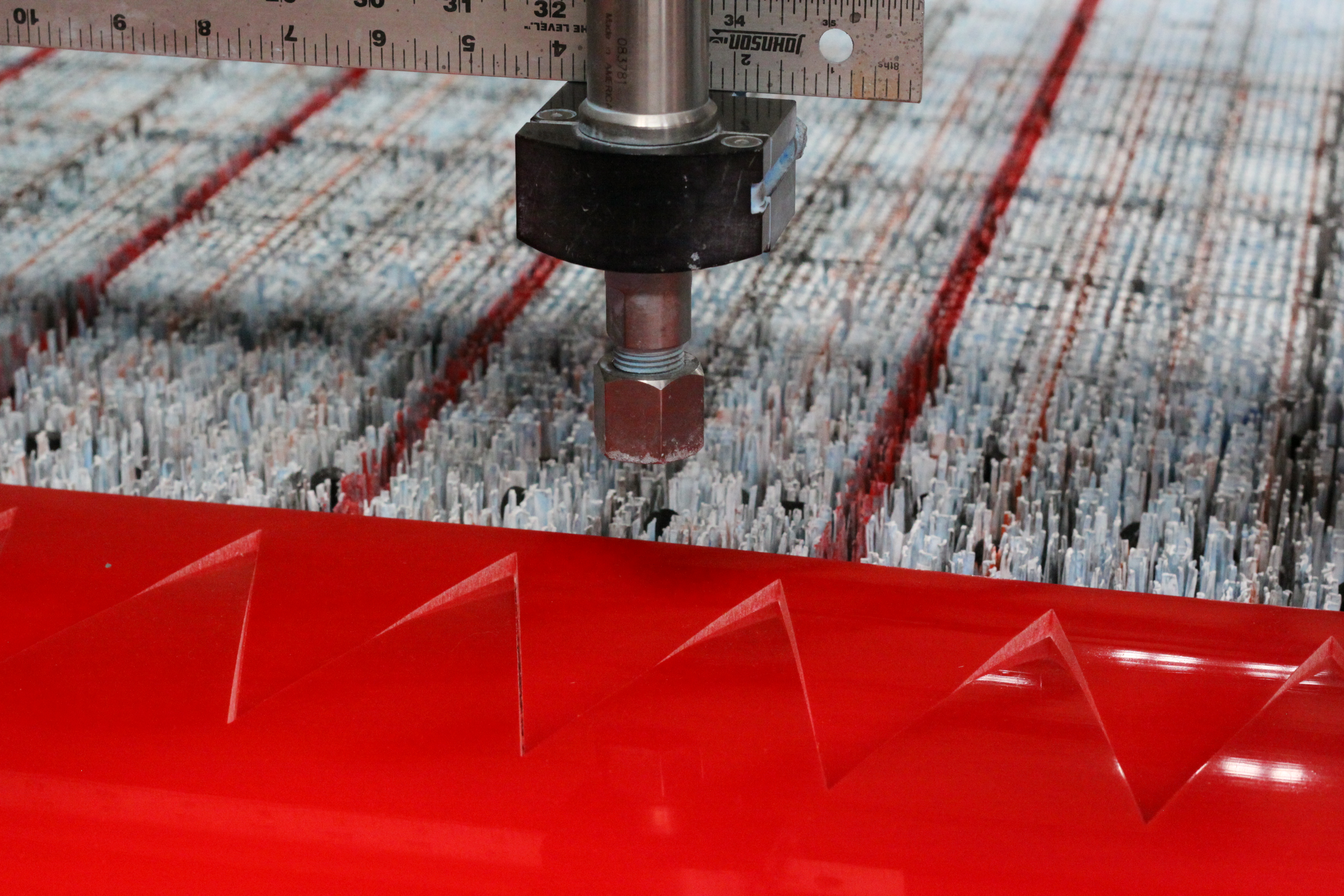

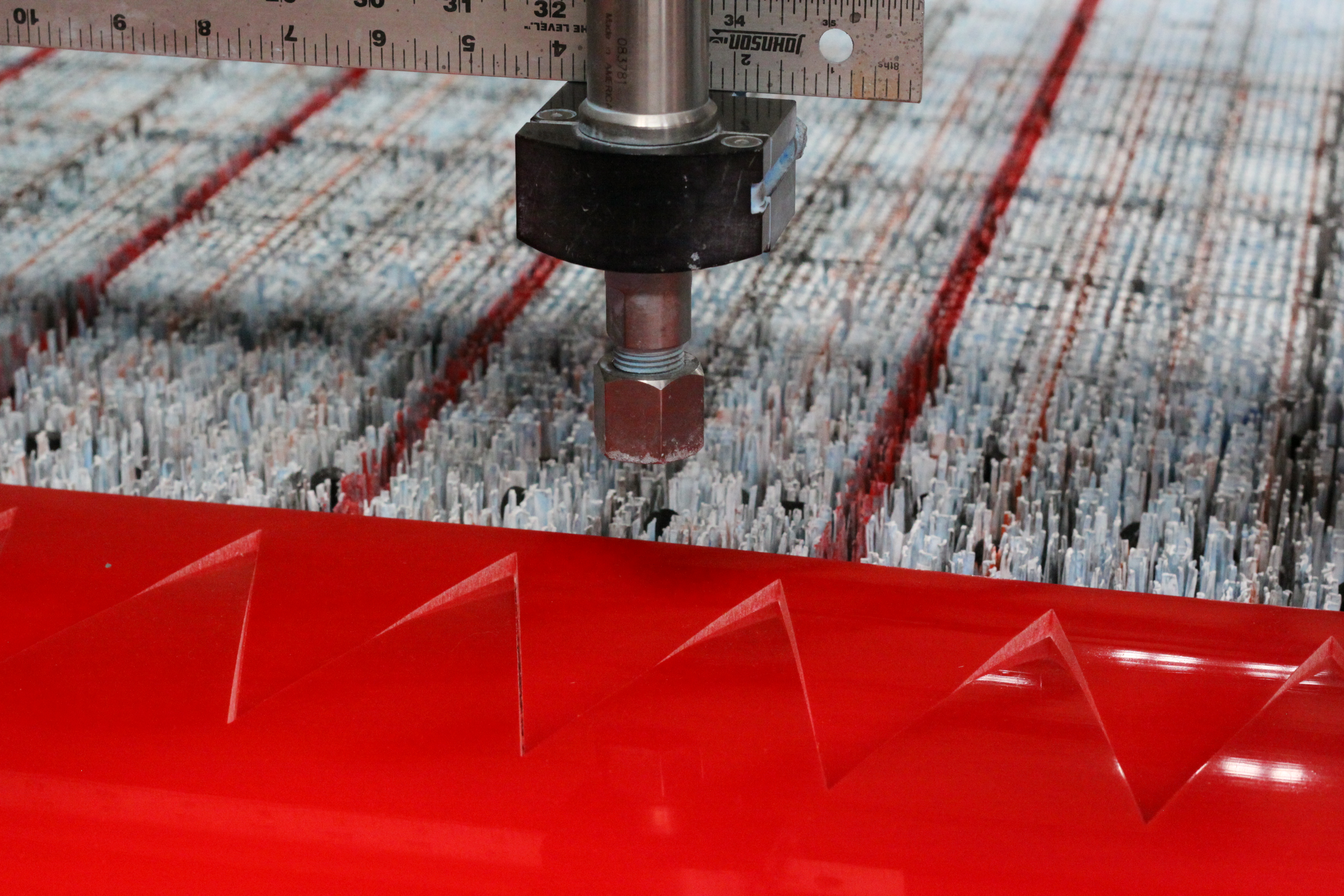

Our waterjet cutters use Computer Numerical Control (CNC) to further enhance its cutting capabilities. This means that our waterjets are equipped with unique software and control consoles that will provide the exact desired results to your finished product.

You provide us with the information of your desired product, and we’ll provide you with a quote, and ultimately a finished product that is exactly what you desire.

This information and the rest of your cutting requirements determine the price of your cutting needs.

The general operating cost for a waterjet $15-$30/hr.

Here are some of the factors that take a part in determining how much your waterjet cutting needs will cost:

- The material you are working with

- The thickness of the material you are working with

- Whether or not hazardous waste disposal will be necessary

- Tolerance level

On top of these project-specific expenses, there are also waterjet-operating expenses that will calculate their way into your cutting cost so that the business can make enough profit to stay afloat and continue to provide cutting services.

The Cost of Operating a Waterjet

Waterjet cutting machines are expensive to purchase, operate, and maintain.

When you request to use a waterjet you are going to have to pay for more than just time occupying and utilizing the machine.

Here are some expenses cutting companies face when using waterjet cutters that will likely factor into your project quote:

- The quality and type of waterjet cutting machine

- The time it will take to cut

- Garnet flow rate

- Programming and data input

- The cost of replacing worn parts

- The cost of abrasive

- The cost of power

- The cost of water

The costs of abrasive, utilities, consumables, and maintenance paired with the regular overhead costs of running a business may be reflected in the cost of providing cutting services.

Compared to other cutting techniques waterjet cutting provides a flawless finished product at a reasonable price.

For more information about waterjets and why they may be the right choice for your project, check out our latest free guide, Waterjet Cutting 101: The Main Benefits of Waterjet Cutting.